The Crank Wheel

|

A while back, I received the following email from Bill Miller in Tennessee...

Hi Gene, I enjoyed reading your article on mowing with a John Deere No. 5 Power Mower. I recently acquired one and after rebuilding and straightening the cutter bar I used it to mow about 20 acres of hay this summer behind a 1955 John Deere 60 and a 1949 John Deere A. It really did a nice job. The mower had not been used in years and the seal leaks on the crank wheel end. I was wondering if you have taken that apart and how is the crank wheel is removed? I assume it has to come off to get to the seal which looks like is located in the bearing cap. Any information on this would be appreciated. Thanks, Bill Miller

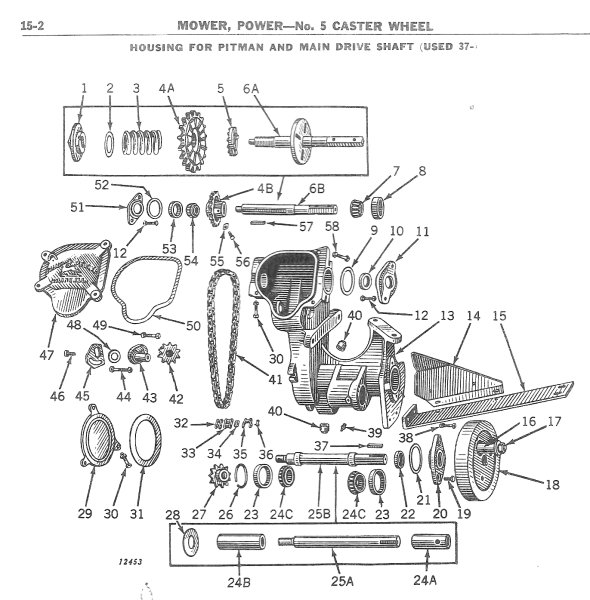

Bill is talking about the part that is numbered 18 in the following diagram. I told him I had never taken one of those wheels off, and that I would assume a puller would be necessary. I asked him to let me know how the job turns out.

|

Bill later submitted the following report....

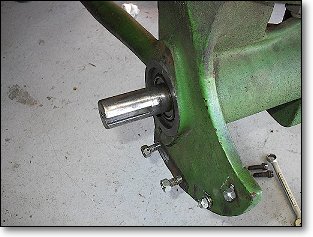

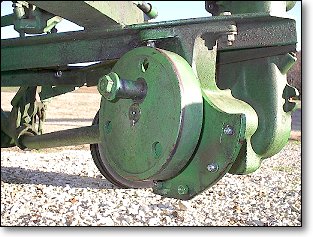

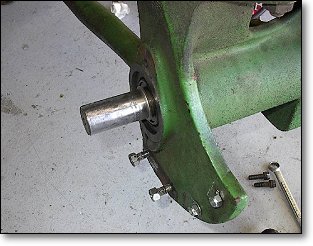

I found that the crank wheel had to be removed with a gear puller to gain access to the cap that holds the lip seal.

I found that the crank wheel had to be removed with a gear puller to gain access to the cap that holds the lip seal.

|

The seal was dried out and the shaft was pitted pretty badly where the seal had run.

The seal was dried out and the shaft was pitted pretty badly where the seal had run.

The crank wheel and shaft is not a press fit, the wheel will rotate freely on the shaft . When the 5/16" square key is inserted then it tightens up. I slid the crank wheel on the shaft and then hammered the key in as far as it would go. I used the key that came out of it (the parts book says it is 5/16" square and 1 3/4" long), I don't think it was tapered. Before I made the final installation, I put the crank wheel on the shaft and hammed the key in a little way. I had to use the gear puller to get it off so it must be enough to keep it in place. |

|

The shaft is 1-1/4" so I used a speedi-sleeve (99125) to fix the sealing surface and replaced the lip seal in the cap. There are several shims between the cap and housing to put the correct load on the tapered roller bearings. I used a small amount of an anaerobic sealant (Loctite 518) on each one to seal.

The shaft is 1-1/4" so I used a speedi-sleeve (99125) to fix the sealing surface and replaced the lip seal in the cap. There are several shims between the cap and housing to put the correct load on the tapered roller bearings. I used a small amount of an anaerobic sealant (Loctite 518) on each one to seal.

|

|

| Go to Gene's Tractor Page |